COLOUR MANAGEMENT SOFTWARE

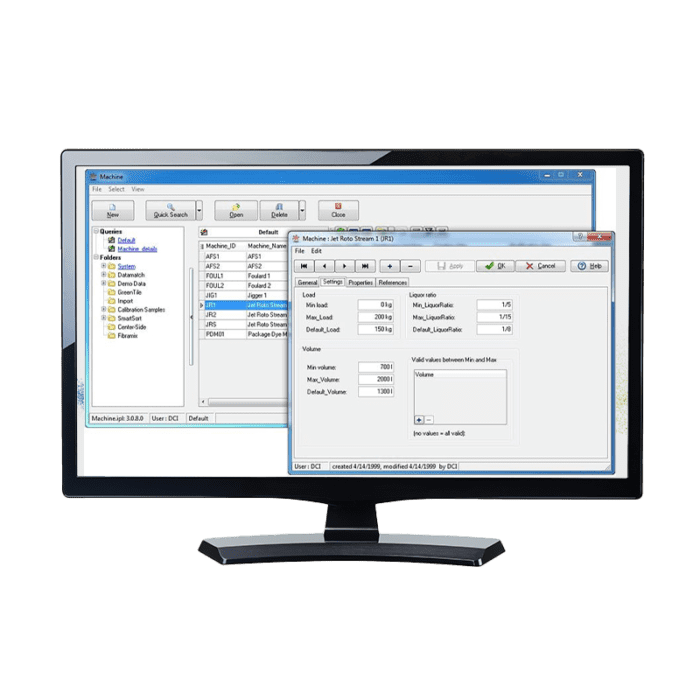

Dye Production Optimisation Software : Process and Ticket

Designed for textile continuous and exhaust dyeing facilities seeking to improve efficiency and accuracy in dye processes, Process and Ticket software solutions utilise and transfer information from an optimised production recipe into the colour lab.

Datacolor PROCESS – Produces the most accurate and efficient production dyeing procedure through rules-based calculations for complex dyeing processes.

Datacolor TICKET – Simple dyelot tickets are produced to ensure accuracy in production dyeing.

Benefits of Datacolor Process and Ticket:

- Automatically generates the best production recipe and dyeing procedure for any colour based on relevant dyeing requirements. Rules-based on liquor ratio, customer, fabric, dye machine, and dyestuff quantity automatically adjust dyeing parameters and chemical amounts to eliminate dyeing errors. Temperature ramp rate and dyeing time are optimised to ensure the most efficient dyeing cycle.

- Dyelot history and quality analysis enable proactive recipe correction to reduce dye adds. Instantly review results for previous dyelots, including all colourimetric data, to identify potential production issues before costly mistakes occur. If a dyelot is off shade, connect to Datacolor Match Textile to generate the most accurate and cost-effective correction to get the dyelot back on shade.

- Supports exhaust and continuous dyeing on any fibre type. Configure dye machines with min/max control of machine capacity, liquor ratio and pickup. Generate simple production recipes or a complete production process, including recipe and process costs. Optional inventory control ensures product availability, while dyelot scheduling guarantees the most efficient use of available equipment.

- Works seamlessly with Datacolor Match Textile and Datacolor Weight to manage the entire textile dyeing process from lab to production. Designed to link with dye machine supervisor and ERP systems, customised integration modules ensure that dye and chemical quantities and process parameters are passed between systems without the need for manual re-entry of data.

Datacolor PROCESS software license of defined level

Optional modules that expand Datacolor PROCESS capabilities to meet individual needs:

Basic level inventory module

- Definition of specific stock conditions (minimum and optimum amount, drum capacity) for each product and lists of products below the minimum quantity

- Automatic product quantity update for those production batches marked as finished, including low stock alert

- Display of added, used and adjusted quantities

- Display of all dyelots by specific product

- Report of stock value with current price and predefined consumption reports

Advanced inventory module

- Manages all reservations, deliveries and orders, with the ability to accommodate variations in product strength and price delivery

Customised form editor module

- Report Explorer for creation and customisation of reports, including:

- Production card customisation

- Report creation using a “wizard,” e.g. list of dyelots by machine and with additions per month; list of recipes using specific dyestuffs

- User-friendly tool for creation and modification of record lists, e.g. all products below the stock minimum

- Export of generated report lists into text files

Dyeorder module

- Groups or splits dyelots that are dyed using the same recipe, for maximum machine capacity usage

- Advanced formula/rules module expands the automated optimisation functionality

- Control of dyestuff combinability

- New bath generation for continuous dyeing corrections

- Display of total forecasted process time in temperature/time diagrams

- Introduction of batch parameters and adaptation of chemicals and parameters

- Calculation/optimisation of production cost for different dyestuff, chemicals and machine operation choice

- Optimisation of chemicals, parameters and dyestuff quantities upon a large choice of conditions, e.g. concentration, customer, machine, LR, etc.

| Feature | Description |

|---|---|

| Dyestuff data management | Input of fibre groups and affinities |

| Automatic creation of dyestuff names | |

| Dyestuff exchange | |

| Quality/Style management | Input of fibre groups and affinities |

| Input of blends | |

| Input of all quality specific parameters/auxiliaries for dyeing behaviour | |

| List and display of all customer or quality-specific colours and standards | |

| Color management | List of all recipes and dyelots per colour |

| Customer management | Input of customer data |

| Customer-specific standard labelling with specific name | |

| Recipe and Process management | Input of complete production recipes, incl. specific recipe information |

| Pass/Fail results of recipes to the standard can be displayed on recipe card | |

| Storage of recipe status (theoretical, laboratory, production) | |

| Printout of lab recipes, simple production recipes and complete production process | |

| Recipe search via different search criteria | |

| Automatic recipe update upon dyestuff concentration changes | |

| Specific information like finishing type, preparation type, technical specification and “to do” date for generation of dyeing process | |

| Creation of modular production recipes including process handling for single treatments and multiple treatments | |

| Handling of exhaust, continuous and semi-continuous processes | |

| Specific linked processes for production adds and re-dyes | |

| Automatic process selection through defined rules | |

| “If-then-else” rules that vary according to dyestuff amounts in the recipe, the affinity or dyeing machine group | |

| Recipe evaluation based on product costs | |

| Tank number and volume can be calculated, depending on total volume (Pad-batch) | |

| Production management | Batch ticketing: simple or advanced with additional information |

| Input and list of defined dyeing lots | |

| Calculation of chemical /dye quantities for the dye kitchen | |

| Output of simple production lots (simple batch ticket) | |

| Output of production adds (production ticket) with additional technical information | |

| Category creation of qualities/styles and customer | |

| Machine management with min/max machine load, liquor ratio, etc. | |

| Choice of dyeing machine with min/max control of machine capacity, liquor ratio, pickup etc. | |

| Input of delivery and required date | |

| Display of Pass/Fail results in the dyelot card | |

| Sorting of production lots | |

| History of production lots and production adds | |

| Cost analysis (recipes and processes) | Cost calculation of lab recipes |

| Production cost calculation incl. dyestuffs and chemicals | |

| Cost comparison of different processes/cost optimisation | |

| History of production cost |

| Module | Added features |

|---|---|

| Basic level inventory module | Definition of specific stock conditions (minimum and optimum amount, drum capacity) for each product and for lists of products below minimum quantity |

| Automatic product quantity update for those production batches marked as finished, incl. low stock alert | |

| Display of added, used and adjusted quantities | |

| Display of all dyelots by specific product | |

| Report of stock value with current price and predefined consumption reports | |

| Advanced inventory module | Manages all reservations, deliveries and orders, with the ability to accommodate variations in product strength and price delivery |

| Customised form editor module | Report Explorer for creation and customisation of reports, including: |

| – Production card customisation | |

| – Report creation using a “wizard,” e.g. list of dyelots by machine and with additions per month; list of recipes using specific dyestuffs | |

| User-friendly tool for creation and modification of record lists, e.g. all products below stock minimum | |

| Export of generated report lists into text files | |

| Dyeorder module | Groups or splits dyelots that are dyed using the same recipe, for maximum machine capacity usage |

| Advanced formula/rules module expands the automated optimisation functionality | Control of dyestuff combinability |

| New bath generation for continuous dyeing corrections | |

| Display of total forecasted process time in temperature/time diagrams | |

| Introduction of batch parameters and adaptation of chemicals and parameters | |

| Calculation/optimisation of production cost for different dyestuff, chemicals and machine operation choice | |

| Optimisation of chemicals, parameters and dyestuff quantities upon a large choice of conditions, e.g. concentration, customer, machine, LR, etc. | |

| Graphical Planboard | Fully integrated with Datacolor PROCESS |

| Visual overview of machine load | |

| Immediate visibility of planned, active and finished dyelots | |

| Dyelots are represented graphically by the target colour | |

| Plan dyelots on any machine with verification for machine suitability | |

| “Drag and drop” functions easily move a dyelot from one machine to another | |

| Advanced scheduler | In addition to the planboard, the scheduler allows time forecasts of the dyehouse |

| *(requires advanced formula module) | |

| Real-time dyelot display | |

| Automated planning after creation of dyelots in Datacolor PROCESS | |

| Incorporation of offline times | |

| Regeneration of dyelots that have been moved to another machine | |

| Printing Module | Grouping of all relevant printing recipes to be kept as one design |

| COMPONENT | MINIMUM REQUIREMENTS |

|---|---|

| Processor | Pentium 4 2.5 GHz |

| Memory | 2 GB |

| Free Hard Drive Capacity | 120 GB |

| Video Resolution | 1024 x 768 True Colour |

| Video Memory | 128 MB |

| CD/DVD Drive | CD Writer |

| Diskette Drive | 1.44 MB |

| Available Ports | (1) RS-232 Serial, (3) USB |

| Printer Port | Parallel or USB |

| Operating System | Windows® XP Pro, SP 2, Windows 10 & 11 |

Colour Management Solutions

Explore Colour Management Software

Dyer Colour Formulation Software: Match Textile

Enhances accuracy and speed of recipe calculation, providing superior first-shot matches.

Pigment Formulation Software: Match Pigment

Amplifies the accuracy of colour development, improving quality control and productivity.

Colour Quality Control Software: Datacolor Tools

Enables objective analysis, reporting, communication and visualisation of accurate colour results.

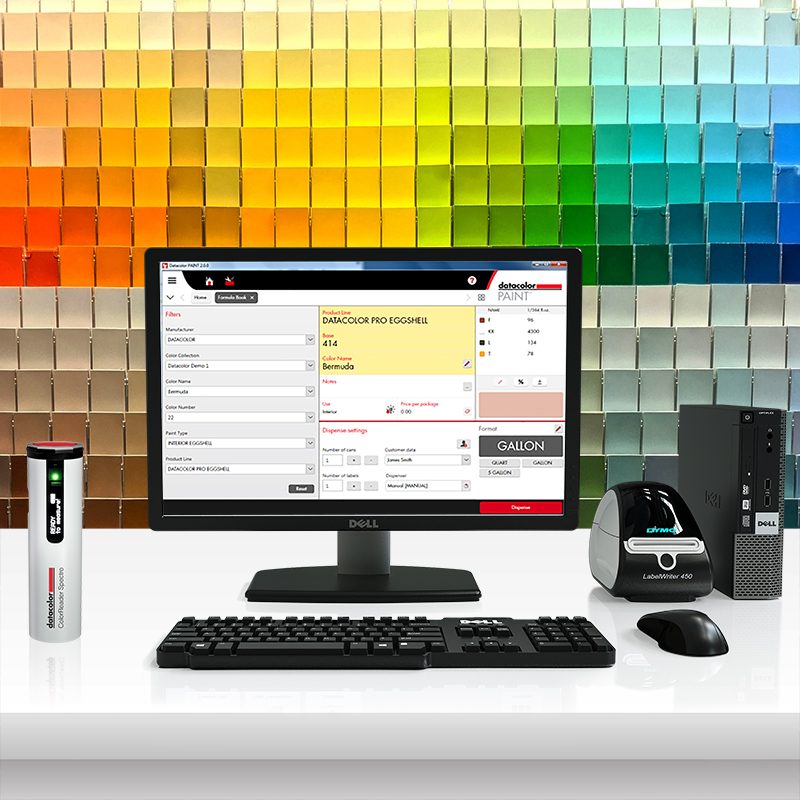

Retail Paint Software: Paint

Not only can you make accurate colour matches every time, but with Datacolor Paint, you can also easily control the paint-matching instruments and dispensers.

Dye Production Optimisation Software: Process and Ticket

Helps your experts manage dye recipes and production dyeing procedures.

Dye Production Optimisation Software: Weigh

Datacolor Weight software interactively guides the drug room operator through the entire weighing process, ensuring that the correct dyes and chemicals are weighed accurately.

Colour Quality Control Software: Datacolor Tools

Retail Paint Software: Paint

Not only can you make accurate colour matches every time, but with Datacolor Paint, you can also easily control the paint-matching instruments and dispensers.

Dye Production Optimisation Software: Process and Ticket

Dye Production Optimisation Software: Weigh

Datacolor Weight software interactively guides the drug room operator through the entire weighing process, ensuring that the correct dyes and chemicals are weighed accurately.